knife hardness tester|fn sharp hardness scale : broker The Best Hardness Ratings For Knives. Regardless of its intended use, any good knife should have a hardness rating between 52 HRC and 64 . Elisângela da Costa Silva, conhecida artisticamente como Elisa Sanches (Rio de Janeiro, 21 de agosto de 1981), é uma modelo, apresentadora, atriz pornográfica e garota de programa brasileira. Elisa é a "pornstar" brasileira mais procurada na maioria dos sites adultos nacionais e internacionais, sendo a atriz com maior número de prêmios no "Oscar do Pornô Nacional

{plog:ftitle_list}

Friv® | FRIV.COM : The Best Free Games! [Jogos | Juegos] Bloxorz. Mad Fish. Super Onion Boy. Smiling Glass Pro Pourer. 4 Colors. Penalty Challenge. Basket Champs. Power Pamplona. Friv Wordsearch. Tic Tac Toe XXO. Fireboy and Watergirl Forest Temple. Fireboy and Watergirl Light Temple. Fireboy and Watergirl Ice Temple.

The Rockwell Hardness Scale is a clear way to measure how hard a knife is, which helps keep quality standards high across the business. If you understand this scale, you’ll be able to make smart decisions and pick the .The Rockwell hardness test uses a diamond-tipped indenter to measure material hardness, providing crucial insights into knife blade quality and performance. This method ensures . The Rockwell Hardness test measures the depth of penetration of an indenter into a material. In the case of kitchen knives, a diamond cone or a hardened steel ball is used to apply a specific load to the blade.

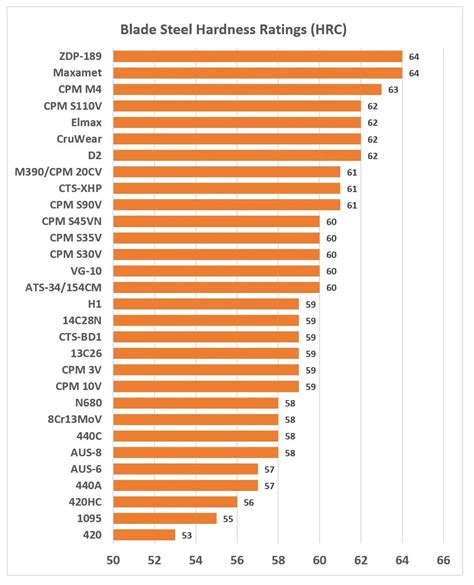

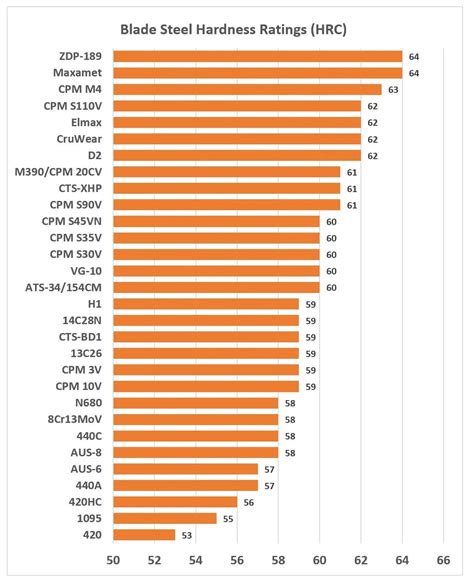

The Best Hardness Ratings For Knives. Regardless of its intended use, any good knife should have a hardness rating between 52 HRC and 64 .

Shop the easy to use Hardness Testing Files from Jantz Supply and quickly test your knife hardness on the Rockwell C Scale.Test your knife hardness on the Rockwell C scale with this testing file set. Files from 40 RC to 65 RC are included in a custom-fitted case, along with complete instructions and a conversion chart for Rockwell to Vickers. The Leeb scale hardness tester is not good for knives, or anything that thin, without careful coupling of the part to a heavier piece. They are intended (and we used them) for thick sections that cannot be moved to the lab, such as pressure vessels, heavy structural steels (thin beam flanges or joist chords/webs are right out), or other .

Edge-On-Up’s less expensive testers are made for occasional, personal use. They provide resolutions of 5 grams (the “PT50B” model) and 25 grams (the “PT50C” model). Prepping the Tester. The synthetic test wire is . This number helps consumers understand the knife's potential for edge retention, as well as its ability to withstand impact and wear. Understanding the Rockwell Hardness Values: Soft Blades (Low Rockwell Hardness): . Hey All In the last 5 months I've been setting up my new knife shop and testing different methods and techniques for annealing, normalizing, hardening and tempering steel. I've invested in High-End steel(s), multiple Quench Oils, a Digitally Controlled Kiln and even Liquid Nitrogen Cryo Equipment. Not to mention a new KMG-TX 2x72 Grinder, Milling Machine, . HRC Rockwell Test - DIY Hardness TestUsually, harder steel increases the likelihood that blade will remain sharp for a longer period of time. Steel hardness .

In this advanced knife making tutorial, I discuss why knife makers should test the hardness of their blades and demonstrate how I use the Ames Model 1 to tes.

rockwell knife hardness scale

With the BESS everyone can test the sharpness of a knife. The Edge-On-Up test tools are relatively affordable. Therefore, you no longer need half a laboratory to end up with reliable results. As long as everyone uses the certified equipment and the certified test medium. As such you measure the sharpness of your knife like every other user in . Rockwell testing can leave a mark on the steel, which is why many makers measure it on a part of the steel that’s concealed by the handle. . 62 RC is very hard so that’s good, it’s important to take the steel material, heat treatment, knife’s purpose, and hardness level into account. When you compare the steel with the hardness, you .

LCD Melt Flow Indexer tv shopping

Mr Volcano Parks 50 Quench Oil for Heat Treating Steel and Knife Steel - 1 Gallon. . Mxmoonfree Metal Hardness Tester Kit, Digital Non-Destructive Leeb Testing with Multi Scales. 4.4 out of 5 stars . The rockwell hardness test measures the knife blade’s ability to resist deformation or indentation under pressure. Different materials used in kitchen knife production can result in varying rockwell hardness ratings. In this section, we will explore the rockwell hardness ratings of various kitchen knife types to help you determine which . Rockwell hardness scale is the most common unit to identify knife steel hardness. When a knife’s hardness is between HRC 45 and the low-50s, we see it as being on the softer side. Any steel that’s higher than the mid-50s is seen as hard. However, once it goes beyond 60, that’s when we label it as very hard.

TIP: A Mohs hardness test is one of the most useful tricks that should be in all rockhounds’ playbooks. Check out the best test kits in the article below: . A common knife has a very similar hardness to glass. So, it can also be used to differentiate whether a mineral is softer or harder than 5. A steel file is harder (6-6.5) than a knife .Also, Rockwell hardness test only reveals the surface hardness of a material and not its internal hardness. Apart from the Rockwell hardness number, other qualities of a knife blade that should be considered to determine the quality of a blade are: metal composition, handle construction, grind type, edge bevel, sharpening requirements, handle .The Rockwell test of hardness HRc refers to the Rockwell Scale of Hardness, part C. The Rockwell scale is widely used by metallurgists to define just how hard a piece of steel is: the higher the number, the harder the steel. . The hardness of a knife is very important as far as its performance and durability. For instance, a harder steel with .

rockwell knife hardness rating

G9645 Hardness Tester Simple in design and easy to operate, yet sensitive and accurate. The G9645 Hardness Tester was designed for measuring Rockwell Hardness values of metals and alloys of all kinds, hard or soft, whether flat, .Shop the easy to use Hardness Testing Files from Jantz Supply and quickly test your knife hardness on the Rockwell C Scale. Shop Jantz for all your knifemaking needs. - | / Save up to % Save % Save up to Save Sale Sold out .

The Grizzly HR150A is the "de-facto" knife maker hardness tester model.Grizzly G9645https://www.grizzly.com/products/Grizzly-Hardness-Tester/G9645?gclid=Cjw. Hardness testing can be applied to various types of materials, some of which are listed below: Metals and alloys. Ceramics. Elastomers. Polymers and plastics. Films. Rocks and minerals. Importance of Hardness Testing. Hardness testing is important for a number of different reasons. The hardness of a material can be a critical parameter in its .

B.O.S.S. Optical Scope - Brinell Hardness Testers. The B.O.S.S. is a Brinell optical scanning system that includes a high resolution video scanning head and imaging software that ensures a fast and accurate reading of Brinell impressions.

One test I talk about a lot in my previous articles is the paper test. For me, this is the easiest and best way to test the sharpness of your knife. All you will need for this test is your knife and a piece of paper. To do this test, try slicing the paper with your knife. If the knife catches the paper and slices it easily, you have a sharp blade.Whether a standard specimen or a thin-walled specimen – the digi test II offers a suitable hardness testing solution for any kind of specimen. For more than 45 years, the Bareiss’s hardness testing technologies have impressed with its interchangeable probe system for hardness testing of different elastic materials and shapes.

Since I am new to Hardness testers, I wanted to make sure this is a good system for testing Knife Hardness. Does anyone know if this will do the job? I'm also open to other options for good quality testers. Last edited: Jun 18, 2019. Reactions: E.Carlson. J. Joker66. Gold Member. Joined Apr 20, 2014 In the knife industry, the Rockwell hardness test is typically used to measure the hardness of the blade at the spine and edge. The Rockwell scale used for knives is typically the C scale, which measures the hardness of hardened steel. To perform the Rockwell hardness test, a diamond or tungsten carbide ball is pressed into the blade with a .

Test your knife hardness on the Rockwell C scale with this testing file set. Files from 40 RC to 65 RC are included in a custom-fitted case, along with complete instructions and a conversion chart for Rockwell to Vickers. These high-quality hardness testing files feature specially curved tips for testing internal slots and grooves as well as .

rockwell kitchen knife hardness

I'm a little controlling by nature, and the not knowing for sure where my blades are coming in on the hardness scale is killing me. In my research, I've come across several portable versions of rockwell hardness testers that have got me intrigued. My shop is very small, it's tiny actually, and I really don't have room for a bench-top model.How to use Rockwell Hardness Files for knife making. Testing files can be used as an affordable way to test the hardness of knife blades after heat treating..

Learn what the Rockwell hardness scale means for kitchen knives. The Rockwell scale is the standard for determining a material's hardness. . The Rockwell hardness test is done by measuring the permanent depth created on a material caused by the force of the indenter. A rounded diamond cone indenter is used for steel as it falls under Scale .

Melt Flow Indexer tv shopping

Charpy Impact Tester (5J) tv shopping

webNSFW. CATARINA PAOLINO ONLYFANS GRATOS NO GRUPO ABAIXO. 99 10. Share. u/Chemical-Carpet1846. • 1 mo. ago. NSFW. CATARINA PAOLINO ONLYFANS .

knife hardness tester|fn sharp hardness scale